GRP Grating vs Steel: Which is Right for Your Project?

Selecting the right flooring, walkway, or platform material is a critical decision in any industrial, commercial, or infrastructure project. From safety and durability to long-term maintenance and cost efficiency, every factor influences performance and overall project value. Today, two of the most widely used options are GRP Grating and steel grating—each offering different strengths and limitations.

As industries evolve, operators are shifting toward materials that deliver greater resilience and reduced lifecycle costs. This has brought composite solutions into focus, particularly GRP Grating, which is now competing head-to-head with traditional steel systems. But which option is truly right for your application?

This comprehensive guide explores their differences in depth, helping engineers, facility managers, and project planners make a confident, informed choice.

Understanding the Materials

What is Steel Grating?

Steel grating is traditionally manufactured from carbon steel or stainless steel and welded or press-locked into a grid structure. It is known for its:

- High load-bearing strength

- Ability to withstand heavy impact

- Familiarity across industries

However, steel is also prone to corrosion, requires regular maintenance, and must often be coated, galvanised, or repainted to maintain performance in harsh environments.

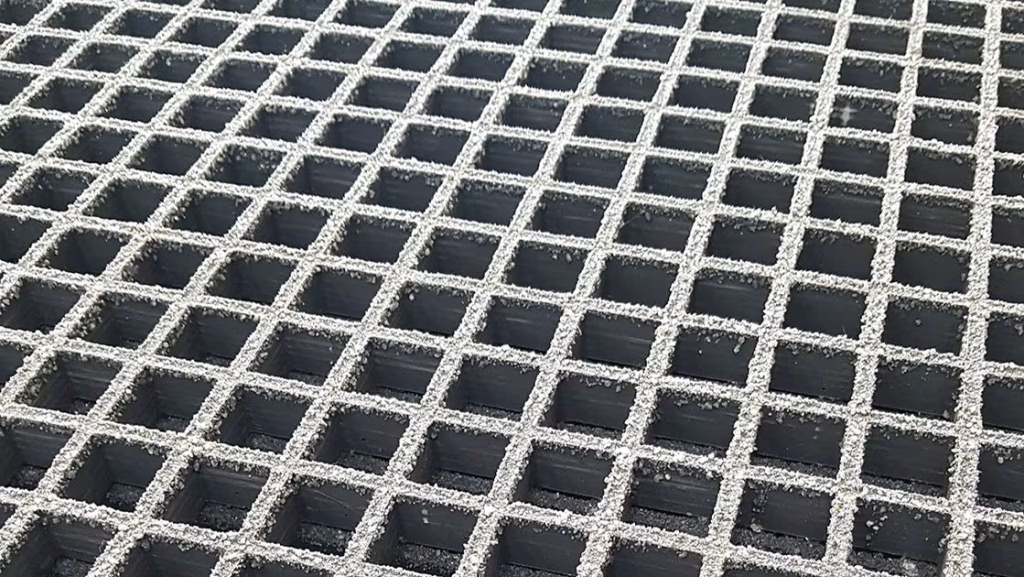

What is GRP Grating?

GRP Grating is a composite product made from glass fibres and thermosetting resin. This combination creates a lightweight, high-strength, corrosion-resistant material suitable for environments where steel may deteriorate quickly. It is available in both moulded and pultruded forms, allowing engineers to choose the ideal structure for load requirements, span lengths, and environmental exposures.

Key Comparisons: GRP vs Steel

To determine which material suits your project best, let’s investigate how they differ across the most important performance categories.

1. Durability in Harsh Environments

Steel is strong, but its biggest weakness is corrosion. Exposure to moisture, chemicals, and saltwater gradually degrades it unless protective coatings are applied.

In contrast, GRP Grating performs exceptionally well in corrosive environments due to its inherent resistance to:

- Acids and alkalis

- Saltwater

- Oils and solvents

- Constant moisture

This makes it especially valuable in industries such as marine, chemical processing, wastewater treatment, and offshore platforms—where steel structures face continuous corrosion risks.

Verdict: GRP provides superior long-term durability in harsh conditions.

2. Strength-to-Weight Ratio

Steel is heavier and denser than composite materials but offers high strength. However, high weight increases:

- Transport costs

- Installation time

- Need for lifting equipment

- Structural load requirements

GRP Grating, while significantly lighter, still provides excellent structural performance for walkways, platforms, and access systems. Its high strength-to-weight ratio makes it easier to handle and install—even in elevated or remote areas.

Verdict: GRP delivers comparable strength with far less weight, improving efficiency.

3. Safety Performance

Safety is a top priority in industrial environments, and material choice impacts multiple safety factors.

Slip Resistance

GRP surfaces are available with integrated quartz grit, providing exceptional anti-slip performance even when wet or oily. Steel requires added coatings or serrations for slip resistance.

Fire and Electrical Safety

Steel conducts electricity and heat. GRP Grating is non-conductive and can be manufactured to be fire-retardant, making it ideal for:

- Electrical substations

- Rail applications

- Chemical plants

- Offshore platforms

Impact Safety

GRP does not dent permanently when struck. Steel can.

Verdict: GRP outperforms steel in slip resistance, electrical safety, and non-conductivity.

4. Installation and Maintenance

Steel grating installation often requires hot-works permits, cutting equipment, and trained personnel. Its heavy weight also demands mechanical lifting and additional labour.

In comparison, GRP Grating can be:

- Cut with simple hand tools

- Installed without specialised machinery

- Carried manually by small teams

- Adapted onsite with minimal disruption

Maintenance is another major cost factor. Steel requires:

- Painting

- Galvanising

- Rust removal

- Periodic inspections

GRP needs almost no maintenance once installed.

Verdict: GRP significantly reduces installation time and long-term upkeep costs.

5. Cost and Lifetime Value

Steel grating usually has a lower initial purchase price. However, lifecycle expenses can increase dramatically due to:

- Corrosion management

- Repainting and recoating

- Replacement

- Downtime during repairs

Although GRP Grating may cost more initially, it offers a lower lifetime cost due to:

- No corrosion

- Minimal maintenance

- Long service life (20–30+ years)

- Reduced installation labour

- No need for specialised coatings

Verdict: GRP is more cost-effective for long-term performance, especially in corrosive or high-maintenance environments.

Industry-Specific Applications

To help determine which option fits your situation, consider how each material performs in different sectors.

Marine & Offshore

- High corrosion makes steel maintenance costly.

- GRP Grating excels due to its resistance to seawater and salt spray.

Preferred choice: GRP

Water Treatment & Utilities

- Constant exposure to chemicals and moisture rapidly degrades steel.

- GRP thrives in acidic, alkaline, wet, and humid conditions.

Preferred choice: GRP

Construction & Infrastructure

Steel is still used for structural load-bearing components, but for flooring, catwalks, and access platforms, GRP Grating offers lighter weight and lower maintenance.

Preferred choice: GRP for access systems; steel for heavy structural beams

Manufacturing & Industrial Plants

Both materials work, but GRP is more suitable for environments involving chemicals, oils, or electrical hazards.

Preferred choice: Mixed depending on the zone

Rail & Transport

Non-conductive properties and excellent slip resistance make GRP Grating a preferred choice for trackside walkways, depot platforms, and maintenance areas.

Preferred choice: GRP

Environmental Impact

Sustainability matters more than ever, and material choices contribute to greener construction practices.

Steel production is energy-intensive, with a significant carbon footprint. It also requires ongoing use of chemical coatings throughout its life.

GRP Grating, while manufactured from composites, offers notable environmental advantages:

- Lower transport emissions due to light weight

- Long service life reduces waste

- Minimal maintenance avoids chemical coatings

- Many types are recyclable at end-of-life

Verdict: GRP has a smaller long-term environmental footprint.

Frequently Asked Questions

1. Is GRP strong enough to replace steel in industrial applications?

Yes. Modern composite technology makes GRP Grating strong enough for most industrial walkways, platforms, and access structures. Pultruded GRP options offer particularly high load capacity.

2. How long does GRP last compared to steel?

GRP typically lasts 20–30 years or more with minimal maintenance. Steel can last a long time as well, but only with regular coatings, galvanising, and rust prevention, which increases lifecycle costs.

3. Does GRP require special installation skills?

No. One of the advantages of GRP Grating is easy installation. It can be cut and fabricated using simple tools without hot-works permits, making it far more convenient than steel.

Conclusion

Choosing between steel and GRP Grating depends on your project’s structural needs, environmental conditions, and budget priorities. Steel remains a strong option for extremely heavy load-bearing applications, but its weight, corrosion issues, and maintenance requirements create ongoing costs.

On the other hand, GRP Grating delivers outstanding long-term performance, safety, and cost efficiency. Its resistance to corrosion, lightweight construction, non-conductive properties, and ease of installation make it an increasingly preferred choice across marine, utilities, rail, chemical processing, and infrastructure sectors.

If you need a durable, safe, and economical solution that excels in demanding environments, GRP Grating is likely the best investment for your project’s future. Discover more insights by visiting our homepage anytime.