Understanding Flexible Wire Manufacturing

In various industries, the efficiency and reliability of electrical connections hinge significantly on the quality of wiring solutions. One noteworthy type of wiring is flexible wire, tailored to meet specific needs in diverse applications. For businesses seeking dependable options, choosing the right Flexible Wire Manufacturer is crucial. In this article, we delve into the essentials of flexible wire, explore its benefits and applications, and provide insight into selecting a manufacturer that meets your requirements.

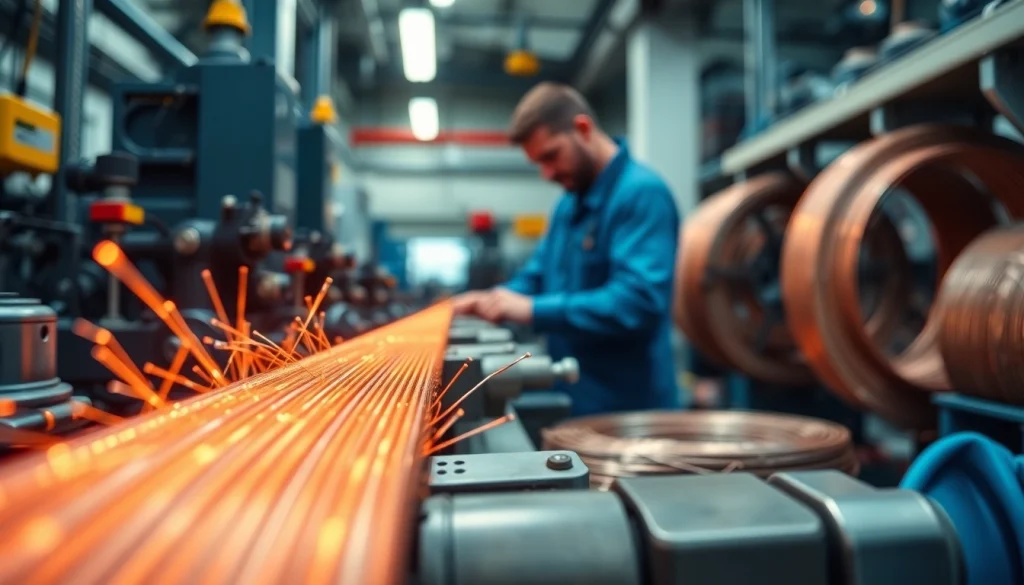

What is Flexible Wire?

Flexible wire refers to wiring that is designed to be easily bent, twisted, and manipulated without breaking or losing its conductivity. It typically consists of numerous fine strands of copper or aluminum encased in an insulating material such as PVC, rubber, or silicone. This structure allows flexible wire to adapt to dynamic environments, making it an ideal choice for applications requiring regular movement or alterations.

Key Benefits of Using Flexible Wire

Flexible wires offer several advantages that make them a preferred choice in many sectors:

- Adaptability: The inherent flexibility allows these wires to conform to various layouts and assembly configurations.

- Durability: Designed to withstand repetitive motion and strains while maintaining performance, flexible wires are less prone to fracturing compared to rigid wires.

- Ease of Installation: The light weight and bendability simplify the installation process, allowing for less time and effort on the job.

- Electrical Efficiency: High conductivity materials ensure minimal resistance, bolstering overall energy efficiency.

Common Applications of Flexible Wire

Flexible wire is widely utilized across various industries due to its unique attributes. Common applications include:

- Automotive: Employed in wiring harnesses, connectors, and sensors, where movement and vibrations are prevalent.

- Robotics: Ideal for robotic arms and joints needing to move freely without compromising electrical connections.

- Consumer Electronics: Frequently found in devices that require flexible connections, such as mobile phones and laptops.

- Industrial Machinery: Used in machinery that demands flexibility amid constant movement and operation.

Factors to Consider When Selecting a Flexible Wire Manufacturer

Choosing the right manufacturer is pivotal to achieving the desired results with flexible wire. Here are critical factors to consider:

Quality Standards and Certifications

It’s essential to select a manufacturer that adheres to stringent quality standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management practices. Assurance of product quality through certified processes ensures reliability and compliance with industry regulations.

Production Capabilities

Evaluate the manufacturer’s production capabilities, including their technology, machinery, and the range of wire specifications they can handle. A versatile manufacturer should be able to accommodate various wire sizes, insulation materials, and custom specifications according to your needs, which will help ensure that you receive the best possible solutions.

Customer Support and Communication

Strong communication and customer support are essential to building a successful partnership. A capable manufacturer should provide timely responses to inquiries, assist with technical questions, and offer support throughout the ordering process. Their ability to understand and meet specific requirements could significantly affect overall satisfaction.

Performance Metrics for Evaluating Manufacturers

Assessing a manufacturer’s performance can help you make a well-informed decision. Key performance metrics to consider include:

Production Efficiency

Examine the manufacturer’s production efficiency, often reflected in their output capacity and turnaround times. Factors such as automated processes and workforce training can enhance efficiency, ensuring that orders are filled promptly without compromising quality.

Quality Control Processes

Investigate the quality control measures the manufacturer has in place. This may include testing and inspection protocols before dispatch to ensure the wires meet specified standards. Robust quality assurance processes can minimize defects and returns, contributing to overall reliability.

Delivery Timeliness

Timeliness in delivery can affect your projects significantly. Evaluate the manufacturer’s track record for on-time delivery, as delays could impact your production schedules and lead to increased costs. Clear communication regarding lead times and shipping can enhance trust and predictability.

Trends in the Flexible Wire Industry

The flexible wire industry is evolving due to technological advancements and shifting market demands. Below are some current trends to consider:

Technological Innovations

Innovation in materials and manufacturing processes has led to enhanced performance characteristics of flexible wires. Advancements such as improved materials that increase flexibility and durability are becoming standard. Additionally, automation in manufacturing increases efficiency and precision, further advancing overall product quality.

Sustainability Practices

Sustainability has become a key consideration in manufacturing. Many manufacturers are adopting eco-friendly materials and processes that minimize waste and energy consumption. Sustainable practices not only benefit the environment but can also appeal to consumers who prioritize sustainable purchasing.

Market Demands and Forecasts

As technology continues to advance, the demand for flexible wires, especially in sectors like renewable energy and electric vehicles, is expected to grow. Manufacturers must stay proactive in adapting to these shifts to meet future needs and remain competitive in the marketplace.

FAQs About Flexible Wire Manufacturing

What materials are typically used in flexible wire?

Flexible wires commonly use conductors made from copper or aluminum, with insulation materials such as PVC, rubber, or silicone to provide protection and flexibility.

How can I ensure quality in flexible wire manufacturing?

To ensure quality, choose manufacturers with appropriate certifications, implement thorough quality control processes, and request samples or test reports before ordering.

What are the lead times for ordering flexible wire?

Lead times can vary based on order size and manufacturer capabilities. Typically, expect anywhere from a few days to several weeks for production and delivery.

Can flexible wires be custom manufactured?

Yes, many manufacturers offer custom solutions, allowing you to specify wire gauge, insulation type, length, and other factors to suit your specific needs.

What are the best practices for maintaining flexible wires?

To maintain flexible wires, avoid over-bending, keep them free from moisture and contaminants, and regularly inspect for wear and damage to ensure safe and reliable use.